Food Logistics

Opendock enables food manufacturers and distributors to keep product moving with precision and care. With automated dock scheduling, in/out logging, and visual proof of deliveries, Opendock helps maintain the freshness of perishable goods and reduce the risks of cross-contamination, delays, and dwell times that can jeopardize food quality and safety.

Fill out the form to request a Opendock demo for your warehouse(s)

How Opendock Helps Food Companies

Customer Case

Red Gold Modernizes Dock Scheduling Processes With Opendock

“Now, 100% of carriers book more than 60k appointments with Red Gold through Opendock annually!”

James PosipankaSupply Chain Manager - Logistics at Red Gold

Customer Challenges

- 2 week-long lead times for appointments

- Long dwell times

- Delays in pickups & deliveries

Solution

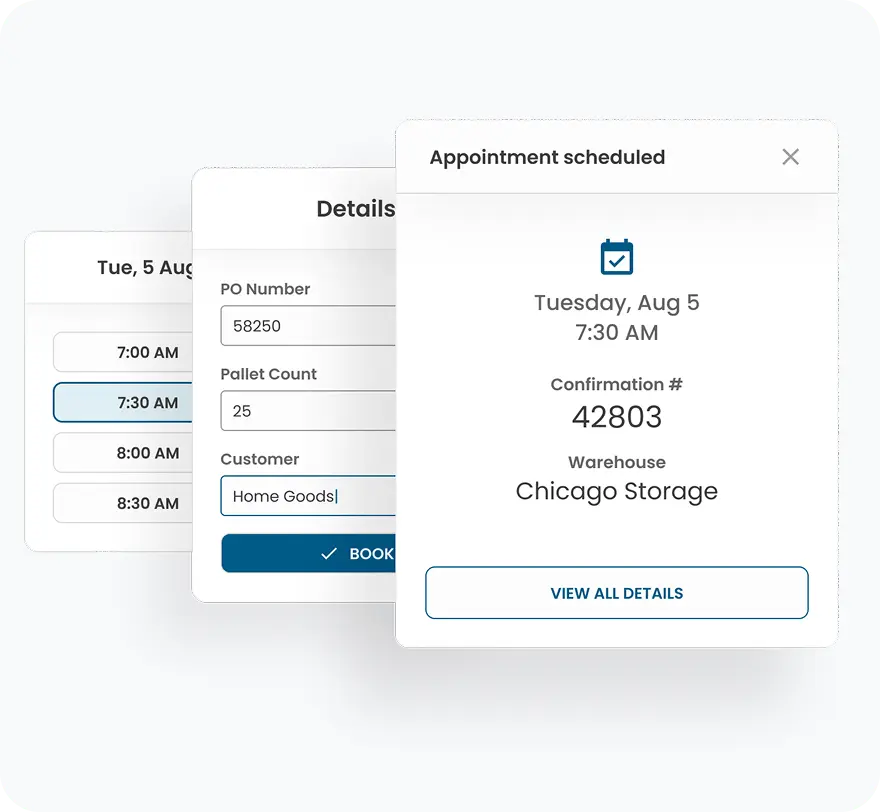

- Online carrier-led scheduling

- Reduce the time it takes carriers to book an appointment

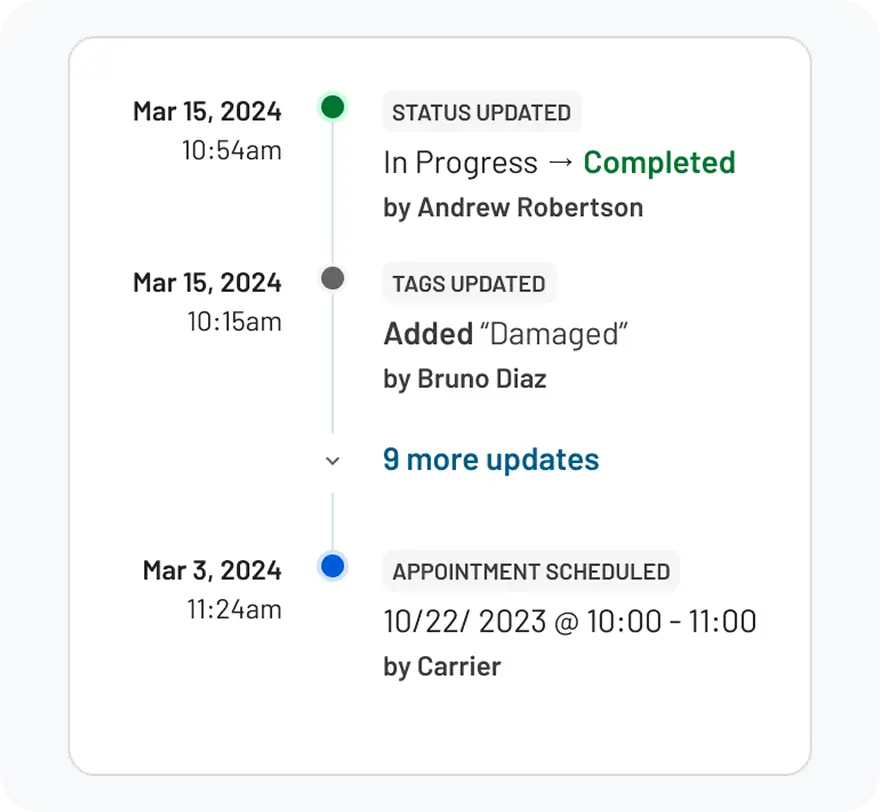

- More visibility into dock schedules

Results

- 90% reduction in lead times for appointments

- Case throughput increased by 18%

- 100% of appointments are scheduled online by carriers